The Nord-Lock Expander System is a specialized pivot pin solution designed and manufactured by the Nord-Lock Group to permanently eliminate lug wear in machinery pivots. It serves as an advanced replacement for traditional straight pins.

Here's a breakdown of the system:

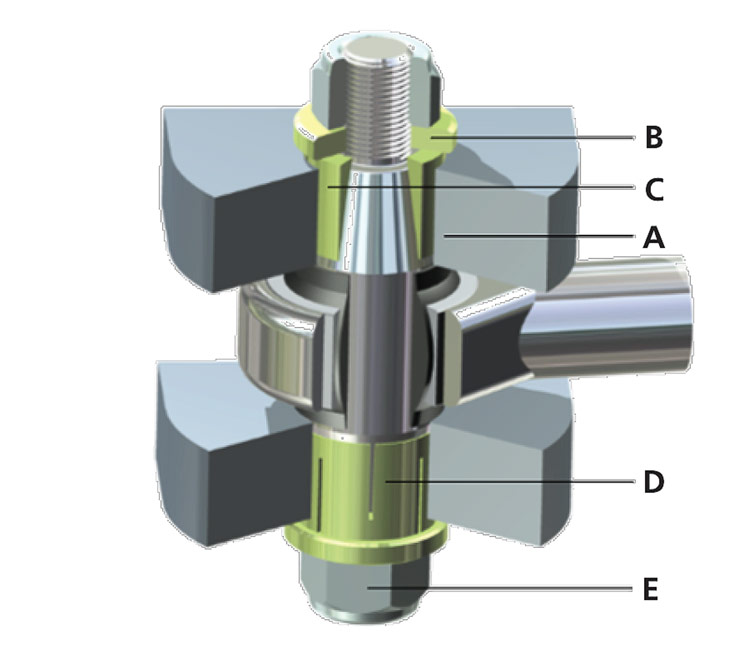

- What it is: The Expander System is an assembly typically consisting of:

- An axle (pin) with tapered ends.

- Two slotted expansion sleeves that fit over the tapered ends.

- Two tension washers.

- Two fasteners (nuts or bolts).

- How it Works:

- The system is installed directly into the existing pivot lugs (bores), even if they are worn.

- As the fasteners are tightened, the tension washers push the expansion sleeves up the tapered ends of the axle.

- The sleeves expand outwards, conforming precisely to the shape of the lug holes, including any wear patterns.

- This creates a tight, pressure-distributed fit, locking the system securely into the lugs from both sides.

- This eliminates the play (clearance) inherent in conventional pin systems, which is the root cause of lug wear.

- The tapered design also facilitates easier installation and removal compared to traditional pins, often using standard hand tools.

Applications: The Expander System is widely used in pivots across numerous industries and heavy-duty machinery, including:

- Construction (excavators, cranes, wheel loaders, bulldozers)

- Mining (haul trucks, shovels, dredgers, breaker booms)

- Forestry (harvesters, grapples)

- Agriculture

- Railways (rolling stock)

- Offshore (meeting specific standards like DNV and API)

- Wind Turbines

- Manufacturing and Processing (steel mills, paper mills)

- Bridges (movable sections)

- Military vehicles

- Custom expedition vehicles