A Nord-Lock washer, often referred to as a Nord-Lock wedge-locking washer, is a specialized type of locking washer designed to securely fasten bolted joints, particularly those subjected to vibration and dynamic loads. It's known for its high reliability in preventing bolt loosening.

Here's a breakdown of its key features and how it works:

- Two-Piece Design: Unlike traditional single-piece washers, a Nord-Lock washer consists of a pair of identical washers.

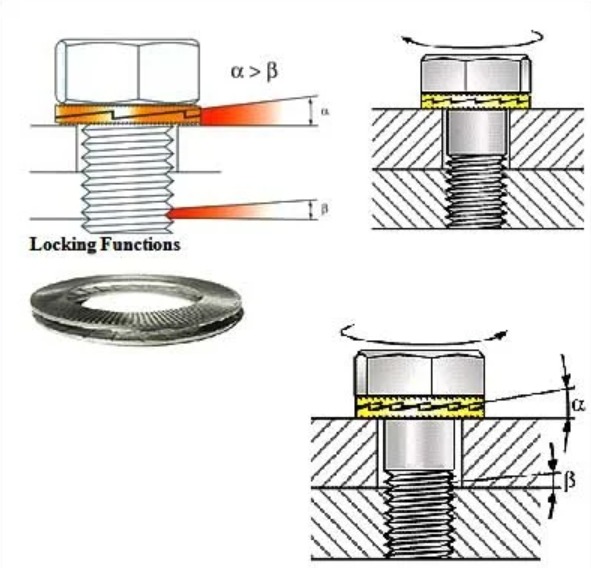

- Wedge-Locking Principle: This is the core mechanism.

- Inner Faces: Each washer has cams or ramps on the face that contacts its paired washer. The angle of these cams (α) is designed to be greater than the pitch angle of the bolt thread (β).

- Outer Faces: The opposite side of each washer has radial teeth or serrations designed to grip the bolt head/nut and the mating surface material.

How it Works:

- When the bolt is tightened, the radial teeth grip the bolt head/nut and the surface underneath.

- The two washers lock together at the cam faces.

- If any loosening rotation begins (due to vibration, dynamic loads, etc.), movement can only occur between the cam faces of the two washer pieces.

- Because the cam angle (α) is greater than the thread pitch angle (β), any rotational movement between the washers creates a slight increase in the clamp load (tension) in the bolt, effectively creating a wedge effect that counteracts the loosening rotation.

- This mechanism locks the fastener securely, relying on tension rather than increased friction like many other locking methods.

Key Advantages:

- High Resistance to Loosening: Extremely effective in preventing bolt loosening caused by vibration and dynamic loads.

- Reliability: Provides a secure and reliable locking function for critical joints.

- Reusability: Can often be reused (though performance might slightly decrease over many cycles, and proper lubrication is recommended).

- Not Dependent on Friction: The locking function is primarily based on geometry (the wedge effect) rather than friction, which can be unpredictable.

- Maintains Preload: Helps maintain the initial clamp load (preload) in the bolted joint.

Junkers Vibration Test

The Junker vibration test (DIN 65151 standard) is used to rigorously assess and compare the security of bolted connections. Performance data, as highlighted in the accompanying diagram, shows Nord-Lock washers maintain consistent clamp load under vibration. This data also validates the unique Nord-Lock wedge-locking principle: note the distinct increase in clamp load during untightening, which confirms the washers' secure locking mechanism.

Typical Applications:

Nord-Lock washers are commonly used in demanding applications where joint failure is critical, such as:

- Heavy machinery (construction, mining)

- Wind turbines

- Railways

- Automotive (especially heavy vehicles

- Aerospace

- Manufacturing equipment

- Structural engineering

In summary, a Nord-Lock washer is a two-piece mechanical lock washer system that uses a unique wedge-locking principle based on tension to reliably prevent bolted joints from loosening under stress, vibration, and dynamic loads.